Tech companies work with a lot of complex equipment when doing their business, but one raw resource is becoming more important to them than ever. Sand is used to construct small, powerful chips for consumer electronics. As the world adopts more digital solutions to everyday problems, the demand for sand has steadily increased over the past decades.

Why Sand is Important

When most think of sand, they’ll think of a sunny beach or the rolling dunes of a desert. The truth is that some forms of sand are more valuable than others, depending on the materials that make it up.

Desert sand is best used for stonework, including new forms of concrete if the sand is treated. Meanwhile, deserts themselves play an important role in regulating the Earth’s temperature and have become iconic for the unique creatures and cultures associated with them. That’s why deserts and desert settings feature heavily in some media, including digital media like iGaming sites. For example, the Sahara Riches Cash Collect slot at Betfair is themed around the world’s most famous desert and the Arabian architecture that’s commonly found in North Africa. Of course, a desert doesn’t necessarily mean it contains sand as the continent of Antarctica shows us.

It’s the other kind of sand – beach sand – which is more valuable to tech companies. In fact, any industry that uses electronics has come to rely on this quickly depleting resource. Even beach sand isn’t made equal, as it depends on how much quartz content the sand has. No sand deposit is the same, as they’re made from billions of worn-down particles of other materials like coral, shells, calcium, gypsum, and the all-important quartz. Quartz contains silica, arguably the most important semiconductor material in today’s tech economy. When a sand deposit has 95% silica content, it’s good to go.

How Sand Becomes Silicon

There are two main ways to source quartz-heavy sand for use in tech fields. The first is by finding the rare beaches and other natural sand deposits that fit the bill. A lot of natural sand, including deserts but also riverbed sand, contains too many impurities or not enough silica. The second way to source quartz sand is from mining. Quartz is everywhere, inside most rock formations and in the clouds of distant planets, as Yahoo! News reports. So, when a mining operation is well underway, a lot of waste sand/gravel is produced and dumped nearby. If the rock has a lot of quartz, or if it’s sandstone, then that waste sand has a lot of silica.

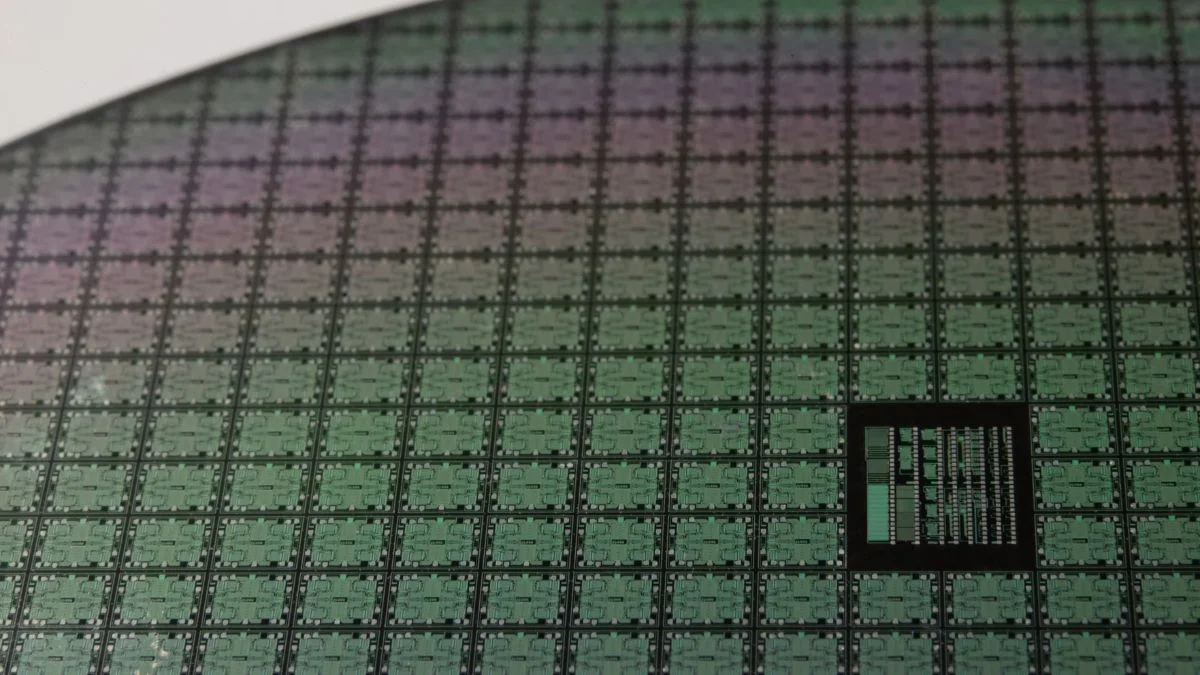

Fortunately, we find a use for that sand by turning it into silicon. When the natural material silica is processed into a crystalline semiconductor wafer, it becomes silicon. Silicon has a diamond-like structure that’s great at transmitting electricity, but is highly conditional, which allows engineers to build more advanced circuits and logic switches inside it. As a result, powerful microelectronics can be created using silicon wafers. This is also how places like Silicon Valley got its name, along with every other big tech hub that has adopted the silicon name.

Given its importance and limited supply, it should come as no surprise that sand is a depleting resource. This is why research is being conducted to treat desert sand for use in construction, to free up other sand deposits for use by tech industries. Elsewhere, we have succeeded at creating artificial quartz with high silica content. Much like desalinating water, it’s a potential solution that hasn’t become economically viable yet but may in the future.

Disclaimer: Gambling involves an element of financial risk and may be addictive. Please play responsibly and at your own risk. This post contains material that may not be legal in your country. Please play subject to applicable law.