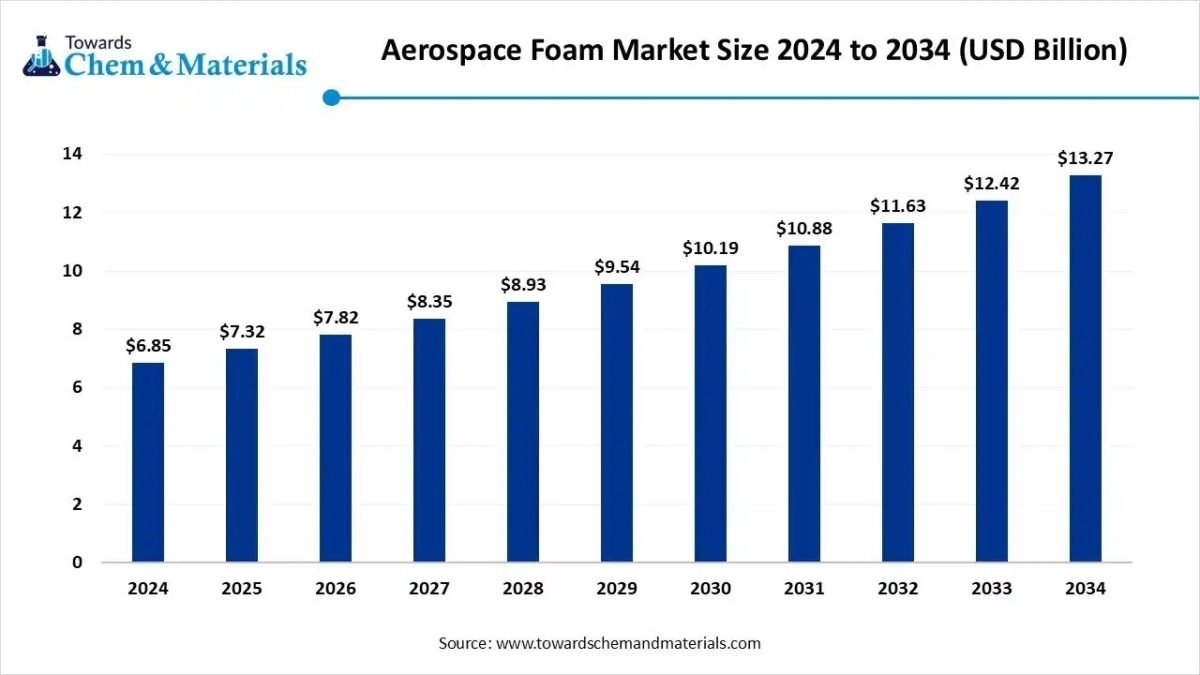

According to Towards Chemical and Materials, the global Aerospace Foam market size is calculated at USD 7.32 billion in 2025 and is expected to surpass around USD 13.27 billion by 2034, growing at a compound annual growth rate (CAGR) of 6.84% over the forecast period 2025 to 2034.

Ottawa, Nov. 14, 2025 (GLOBE NEWSWIRE) — The global aerospace foam market size was valued at USD 6.85 billion in 2024 and is anticipated to reach around USD 13.27 billion by 2034, growing at a compound annual growth rate (CAGR) of 6.84% over the forecast period from 2025 to 2034. North America dominated the aerospace foam market with a market share of 40% in 2024. The growth of the aerospace foam market is driven by increasing demand for lightweight and high-performance materials that enhance fuel efficiency and aircraft performance. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

The Complete Study is Now Available for Immediate Access | Download the Sample Pages of this Report@ https://www.towardschemandmaterials.com/download-sample/5939

What is Aerospace Foam?

The aerospace foam market in 2024 represented a rapidly expanding sector driven by growing demand for lightweight and high-performance materials in aircraft manufacturing. Aerospace foams are widely used for insulation, cushioning, vibration dampening, and soundproofing in both commercial and military aircraft. The market growth was supported by increasing air travel, fleet modernization programs, and the rising production of next-generation aircraft.

Polyurethane, polyethylene, and melamine foams dominated due to their superior thermal resistance, flexibility, and durability. Moreover, advancements in material science and a focus on fuel efficiency encouraged the use of lightweight foams to reduce overall aircraft weight. Overall, the aerospace foam market continued to evolve through innovation, sustainability efforts, and expanding applications across the aviation industry.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.comAerospace Foam Market Report Highlights

- The North America aerospace foam market dominated the global market and accounted for the largest revenue share of 40% in 2024.

- The Asia Pacific, including key markets such as China and India, is the fastest-growing region in the aerospace foam industry, capturing around 11.14% of global demand.

- Based on foam type, the Polyurethane (PU) segment dominated the global aerospace foam market and accounted for the largest revenue share of 35.10% in 2024.

- By foam type, the polyurethane segment is expected to grow at the fastest CAGR of 7.44% from 2025 to 2034

- Based on End-use, the Commercial aviation segment held the largest revenue share of 30.14% in 2024.

- By End-use, The general aviation segment is expected to grow at a substantial CAGR of 6.65% during the forecast period.

- Based on Application, the Cabin walls & ceilings led the aerospace foam industry, accounting for a revenue share of 27.19% in 2024.

- By application, the flight deck pads segment is expected to grow at a substantial CAGR of 6.7% over the forecast period.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5939

Aerospace Foam Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 7.82 Billion |

| Revenue forecast in 2034 | USD 13.27 Billion |

| Growth rate | CAGR of 6.84% from 2025 to 2034 |

| Historical data | 2021 – 2024 |

| Forecast period | 2025 – 2034 |

| Quantitative units | Revenue in USD million/billion, volume in kilotons, and CAGR from 2025 to 2034 |

| Report coverage | Revenue forecast, volume forecast, competitive landscape, growth factors, and trends |

| Segments covered | Foam type, application, end-use, region |

| Regional scope | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Country Scope | U.S.; Canada; Mexico; Germany; UK; France; Italy; China; India; Japan; South Korea; Brazil; Argentina; GCC Countries; South Africa |

| Key companies profiled | Boyd Corporation; Evonik Industries AG; ERG Aerospace Corporation; SABIC; BASF SE; ZOTEFOAMS PLC; General Plastics Manufacturing Company; Solvay; UFP Technologies, Inc.; Recticel NV/SA; NCFI Polyurethanes; DuPont; Rogers Corporation; ARMACELL |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Read More News : Polymers Market Size to Worth USD 1,351.59 Billion by 2034

Read More News : Polyolefin Market to Grow at CAGR of 4.88% Reaching 371.54 Million Tons by 2034

Read More News : Recycled Polyolefin Market Size to Exceed USD 144.2 Billion by 2034

Read More News : Polystyrene Market Volume to Reach 62.33 Million Tons by 2034

Major Government Initiatives for the Aerospace Foam Industry

- Formulating national aerospace policies to create a strategic vision for the sector’s growth.

- Fostering research and development (R&D) through public funding and collaboration between government agencies (like DRDO and NAL), academia, and private players.

- Promoting indigenous manufacturing and raw-material competitiveness through programs like “Make in India” and “Atmanirbhar Bharat” to reduce reliance on foreign suppliers.

- Implementing stringent regulatory standards for fire, smoke, and toxicity (FST) properties, driven by bodies like the FAA and EASA, which push the development of advanced, high-performance foam materials.

AI Redefining the Skies: The Impact on the Aerospace Foam Industry

Artificial intelligence (AI) is transforming the aerospace foam industry by optimizing material design, production processes, and quality control. Through AI-driven simulations and predictive analytics, manufacturers can develop foams with improved thermal resistance, strength, and weight characteristics tailored for specific aerospace applications. Machine learning algorithms help detect defects and enhance consistency during manufacturing, reducing waste and production costs. AI also enables smart supply chain management by forecasting demand and streamlining inventory for aerospace components.

Major Trends of the Aerospace Foam Market

- Focus on Lightweighting and Fuel Efficiency: The aerospace industry is focused on reducing aircraft weight to improve fuel efficiency and lower operating costs, and aerospace foams play a key role due to their high strength-to-weight ratio. This weight reduction also contributes to decreased carbon emissions and compliance with environmental regulations.

- Emphasis on Fire Resistance and Safety Standards: There is a growing demand for advanced foam materials that offer superior fire resistance, low smoke emission, and enhanced impact absorption to meet strict aviation safety regulations. These safety features are crucial for passenger and crew protection and drive the development of high-performance foams.

- Integration of Sustainability and Technological Innovation: The market is moving towards sustainable foam options like bio-based and recyclable materials to lessen the environmental impact of the aerospace industry. At the same time, technologies like additive manufacturing and advanced molding are allowing for the efficient creation of customized foam structures for specific aircraft uses.

Market Opportunity

Expanding Opportunities in Lightweight and Sustainable Aircraft Materials

One major opportunity in the aerospace foam market lies in the growing demand for lightweight and sustainable materials to improve aircraft fuel efficiency and reduce emissions. As airlines and manufacturers prioritize energy conservation, advanced foams with enhanced strength, insulation, and recyclability are becoming essential components in modern aircraft design. The development of bio-based and recyclable foams presents new avenues for innovation and compliance with global environmental regulations.

Additionally, the increasing production of electric and hybrid aircraft is creating fresh demand for high-performance foams that support thermal management and noise control. This shift towards sustainability and performance optimization positions lightweight aerospace foams as a key growth opportunity in the industry’s future.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5939

Aerospace Foam Market Segmentation Insights

Foam Type Insights

In 2024, the polyurethane (PU) foam segment led the market, due to its exceptional versatility, durability, and lightweight characteristics. PU foams are widely used in aircraft seating, cabin interiors, insulation, and soundproofing applications because of their superior comfort and performance. Their excellent thermal and acoustic insulation properties make them ideal for enhancing passenger comfort and energy efficiency. Additionally, advancements in flame-retardant and eco-friendly PU formulations have increased their suitability for strict aerospace safety standards.

The polyethene foam segment is growing fastest over the forecast period, driven by its excellent impact resistance, lightweight nature, and superior cushioning properties. PE foams are extensively used in aircraft packaging, insulation, and vibration-dampening applications to protect sensitive components and improve structural integrity. Their closed-cell structure provides excellent moisture and chemical resistance, ensuring long-lasting performance in demanding aerospace environments.

Application Insights

In 2024, the cabin walls & ceilings segment dominated the market, due to the rising demand for lightweight, sound-absorbing, and thermally efficient materials in aircraft interiors. Aerospace foams in this segment are essential for enhancing passenger comfort by providing effective noise insulation and temperature control. The use of advanced polyurethane and polyethylene foams helped reduce overall aircraft weight while maintaining structural strength and fire resistance.

The flight deck pads segment is second-largest segment, leading the market, driven by the growing emphasis on pilot comfort, safety, and fatigue reduction during long flight operations. Aerospace foams used in flight deck pads offer superior cushioning, vibration absorption, and ergonomic support, enhancing pilot performance and concentration. The use of lightweight and fire-resistant foams, such as polyurethane and polyethylene, helped meet stringent aviation safety and efficiency standards.

End-use Insights

The commercial aviation segment dominated the market in 2024, due to the rapid expansion of global air travel and rising demand for fuel-efficient, passenger-friendly aircraft. Airlines increasingly adopted advanced foam materials for seating, cabin insulation, and soundproofing to enhance comfort and reduce aircraft weight. Polyurethane and polyethylene foams were widely used for their durability, flame resistance, and superior thermal properties.

The general aviation segment is growing fastest over the forecast period, due to the increasing production of private jets, small aircraft, and business aviation fleets. Lightweight and durable foams were extensively used in seating, interior panels, and insulation to enhance comfort and performance while maintaining fuel efficiency. The growing preference for luxury and customized interiors among private aircraft owners further boosted demand for high-quality foam materials.

Regional Insights

North America Soars Ahead as the Dominant Force in the Aerospace Foam Industry

The North America aerospace foam market size is valued at USD 2.93 billion in 2025 and is expected to reach USD 5.32 billion by 2034, growing at a CAGR of 6.86% from 2025 to 2034.

North America dominated the market in 2024, driven by its strong aerospace manufacturing base and the presence of leading aircraft producers such as Boeing and Lockheed Martin. The region’s high investment in defense, commercial aviation, and space exploration fueled demand for advanced foam materials with superior insulation and safety properties. Continuous innovation in lightweight and flame-retardant foams supported the development of next-generation aircraft designed for fuel efficiency and passenger comfort.

Canada Aerospace Foam Market Trends

Canada’s market in 2024 showed steady growth driven by demand from commercial aviation, defense, and space exploration sectors. The country’s focus on advanced manufacturing and high-quality aerospace components encouraged the adoption of lightweight and durable foams for seating, insulation, and soundproofing. Investments in research and development enabled the production of innovative foams with improved fire resistance, thermal insulation, and vibration dampening properties.

Asia Pacific: The Center for Aerospace Foam Market Expansion

Asia Pacific emerged as the fastest-growing region in the market in 2024, fueled by rapid expansion in aviation infrastructure and increasing aircraft production. Countries such as China, India, and Japan invested heavily in commercial and defense aviation, boosting demand for lightweight and durable foam materials. The growing middle-class population and surge in air travel further accelerated the need for comfortable and energy-efficient aircraft interiors.

India Aerospace Foam Market Trends

India’s market in 2024 experienced significant growth due to the rapid expansion of the country’s civil and defense aviation sectors. Increasing aircraft manufacturing, maintenance, and refurbishment activities drove demand for lightweight and high-performance foam materials. Polyurethane and polyethylene foams were widely adopted for seating, insulation, and vibration control to enhance passenger comfort and aircraft efficiency.

➤ Contact Us: sales@towardschemandmaterials.com | ☎ +1 804 441 9344

Top Companies in the Aerospace Foam Market & Their Offerings:

- Boyd Corporation produces custom-engineered thermal and acoustic insulation using lightweight, fire-resistant open-cell polyimide SOLIMIDE® foams.

- ERG Aerospace Corporation is the sole manufacturer of Duocel® foam, a rigid, open-cell material made from metals or ceramics used for structures and heat exchangers.

- SABIC provides high-performance thermoplastic resins like ULTEM™ and specialized SABIC® PP-UMS foam resins for lightweight interior components with superior fire resistance.

- ZOTEFOAMS PLC manufactures advanced, lightweight, closed-cell crosslinked foams such as ZOTEK® F for aviation and aerospace interiors, offering excellent FST properties.

- General Plastics Manufacturing Company offers high-density polyurethane foam products, including its LAST-A-FOAM® series, used as core materials for composite structures and insulation.

- Solvay provides high-performance specialty polymers and composite materials used in producing lightweight foam cores and components for aerospace applications.

- UFP Technologies, Inc. provides custom-engineered foam components and solutions for aerospace applications, including seating, insulation, and protective packaging.

- NCFI Polyurethanes specializes in producing flexible and rigid polyurethane foam systems for aerospace insulation, cushioning, and structural applications.

- DuPont supplies advanced material solutions, including high-performance polymer-based foams or ingredients used in foam manufacture for demanding aerospace requirements.

More Insights in Towards Chemical and Materials:

- Polyolefin Market Volume and Forecast 2025 to 2034

- Plastics Market Size to Worth USD 984.11 Billion by 2034

- Polyethylene Market Volume to Hit 158.1 Million Tons by 2034

- Low-Density Polyethylene (LDPE) Market Size to Reach USD 80.34 Billion by 2034

- Polyethylene Glycol (PEG) Market Volume to Exceed 788,565.1 Tons by 2034

- Polyethylene Wax Market Size to Reach USD 3.56 Bn By 2034

- Polyethylene Terephthalate (PET) Market Size to Reach USD 68 Bn by 2034

- Mechanical & Chemical Recycling of Polyethylene Market Size and Share 2034

- Polymers Market Size to Reach USD 1,351.59 Billion by 2034

- Europe Plastic Market Size to Surpass USD 223.02 Bn by 2034

- Plastic Adhesives Market – Forecast & Report | 2025 – 2034

- Plastic Injection Molding Market Size to Worth USD 17.65 Bn by 2034

- Polyolefin Market Volume to Reach 371.54 Million Tons by 2034

- U.S. Plastic Compounding Market Size to Hit USD 22.96 Bn by 2034

- Polypropylene Market Volume to Reach 135.05 Million Tons by 2034

- Polystyrene Market Volume to Reach 62.33 Million Tons by 2034

- Recycled Polyolefin Market Size to Reach USD 144.2 Billion by 2034

- Polyolefin Market Volume to Reach 371.54 Million Tons by 2034

- Europe Specialty Polymers Market Size to Surpass USD 72.19 Bn by 2035

- Polymer Coated Fabrics Market Size to Hit USD 40.13 Bn by 2035

- Asia Pacific Specialty Polymers Market Size to Surpass USD 70.70 Bn by 2034

- Polymer Foam Market Size to Surge USD 273.58 billion by 2034

- U.S. Polymer Foam Market Size to Hit USD 22.83 Billion by 2034

- Polymer Chameleon Market Size to Reach USD 1,225.52 Mn by 2034

- Specialty Polymer Market Volume to Reach 19.25 Million Tons in 2025

- Bioresorbable Polymers Market Volume Reach 3,839.1 kilotons by 2034

Aerospace Foam Market Top Key Companies:

- Boyd Corporation

- Evonik Industries AG

- ERG Aerospace Corporation

- SABIC

- BASF SE

- ZOTEFOAMS PLC

- General Plastics Manufacturing Company

- Solvay

- UFP Technologies, Inc.

- Recticel NV/SA

- NCFI Polyurethanes

- DuPont

- Rogers Corporation

- ARMACELL

Recent Developments

- In April 2025, Insperial, a portfolio company under Adagia Partners, acquired MGR Foamtex, a UK-based manufacturer specializing in advanced soft-goods and passenger upholstery systems for aircraft interiors. The acquisition integrates MGR’s engineering and manufacturing expertise with Insperial’s global sales footprint, positioning the combined group to enhance growth, innovation, and market reach across the aerospace interior segment.

- In February 2025, Trelleborg Sealing Solutions expanded its aerospace portfolio by acquiring Aero-Plastics Inc., a U.S. manufacturer specializing in precision injection molding, thermoforming, and machining of high-performance polymers for aircraft interiors, including window reveals and blind assemblies. The deal, valued at approximately SEK 150 million (~USD 15.3 million) and finalized in April 2025, adds significant capacity, technical expertise, and value-added services like assembly, engraving, and painted finishes.

- In April 2025, Ecoxote PE/R LD24 FR was launched by Zotefoams at the Aircraft Interiors Expo (AIX). This new foam was added to the company’s “sustainability” range and was officially introduced at the event on stand 5E36.

Aerospace Foam Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Aerospace Foam Market

By Foam Type

- Polyurethane Foam

- Polyethene Foam

- Melamine Foam

- Metal Foam

- Polyimide Foam

- Polyethene Terephthalate Foam

- Polyvinyl Chloride Foam

- Speciality High Performance Foam

By Application

- Flight Deck Pads

- Cabin Walls & Ceilings

- Aircraft Seats

- Aircraft Floor

- Others

By End-use

- General Aviation

- Commercial Aviation

- Military Aircraft

- Rotary Aircraft

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5939

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. Business Upturn takes no editorial responsibility for the same.