The advent of 3D printing technology has unleashed a revolution in car manufacturing, fundamentally transforming traditional processes. As automotive engineers and designers embrace the capabilities of 3D printing, the industry is witnessing a paradigm shift in how vehicles are conceptualized, prototyped, and ultimately brought to life.

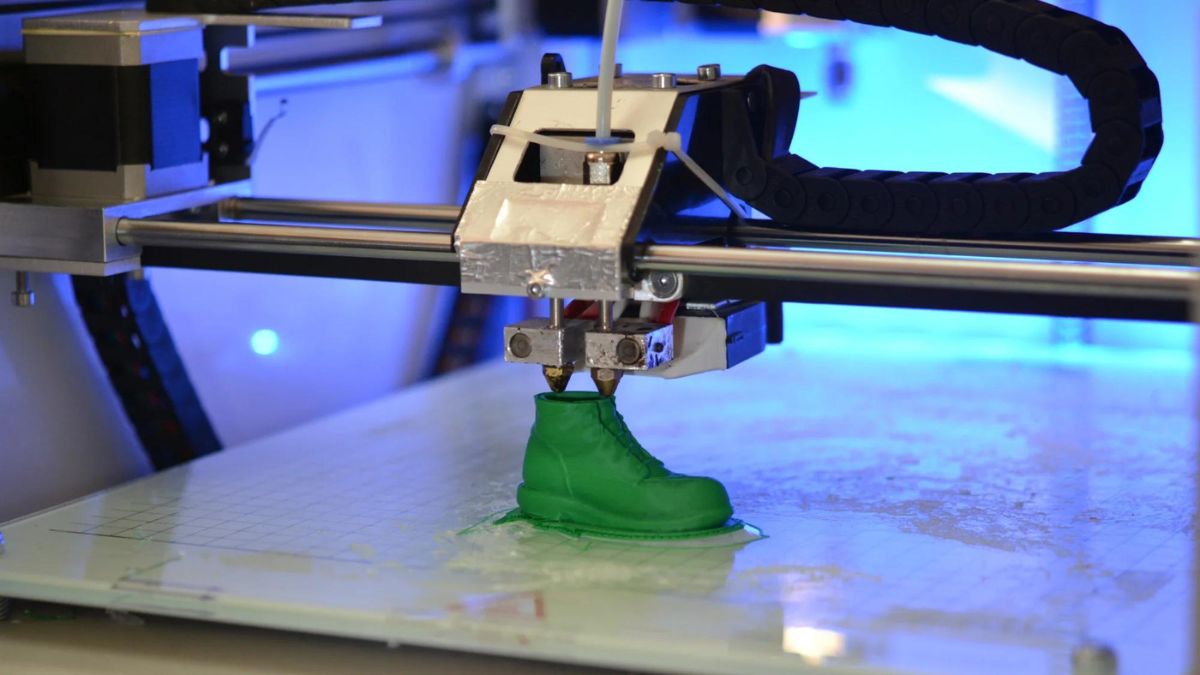

3D printing allows for the creation of intricate and complex components with unprecedented precision. From prototyping to producing lightweight yet robust parts, this technology is streamlining the manufacturing process and enabling a level of customization that was once unimaginable. Automakers are now leveraging 3D printing for rapid prototyping, reducing development time, and enhancing overall efficiency.

The environmental impact of 3D printing is also noteworthy, as it reduces waste compared to traditional manufacturing methods. As the technology continues to evolve, it holds the potential to revolutionize not only the production of vehicles but also the entire supply chain, paving the way for a more sustainable and agile automotive industry.

The integration of 3D printing into car manufacturing processes signifies a transformative era for the automotive industry. As the technology matures, its impact on efficiency, customization, and sustainability will undoubtedly shape the future of how cars are designed and produced.